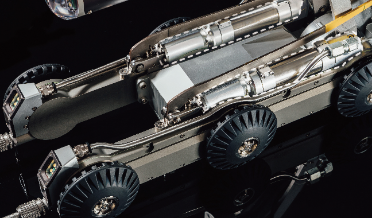

RoboCrawler S

The strong driving performance and a completely submersible

crawler allow users to use the equipment even at a very rough and obstructive pipeline.

RoboCrawler S

RoboEye S

RoboReel S

RoboController S

RoboCrawler S

RoboEye S

RoboReel S

RoboController S

Easy and Intuitive Transformation

First of all, our tractor is largely divided into three units: the robot body, vertical elevation lift units and wheel frame units.

Each of these three units is independently modularized and can be connected to each other by connecting cables, which can create various shapes and sizes of robots in infinite combinations, when combined and used with Cube-Cell Block (CCB) and Spherical Extension Kit (SEK).

When photographing a large box-shaped pipeline, an egg-shaped pipeline, or even in a large gradient, in all of these cases, our expansion and transformation solutions of RoboCrawler S provides an outstanding effect.

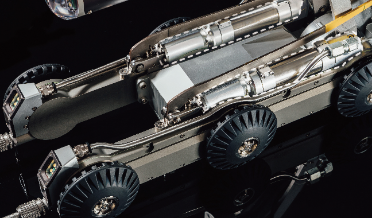

One-Touch Wheel Replacement Process

The four kinds of wheels that can cope with the various diameter sizes of pipelines can be easily replaced by one touch method.

Tractor RoboCrawler S is a single standard model that can investigate at a minimum of 8-inch(200mm) diameter tube and up to 50-inch(1250mm) diameter tube when used with an extended block (CCB or SEK).

Also, if a separate mini tractor is used, small pipes of 5-inch (125mm) to 10-inch(300mm) diameter tube can be investigated as well.

This suggests that these two units can carry out investigation service for most of the pipelines in which the users would want to investigate on, and that there is a clear difference between RoboCrawler S and other brand products since users would have to purchase at least three units individually and pay a high cost.

Total Water Proof

The RoboCrawler S is designed with a double chamber seal structure with Q-ring adopted, completely defending the external water that can be invaded by the axis

of the rotating wheel. In addition, unlike the existing products in box-shaped structure when waterproofing mechanisms were penetrated on the axis and the expensive motors and PCBs got damaged immediately, RoboCrawler S has an oil fence inside the Wheel Frame unit, which fundamentally prevents the robot from being damaged by external water.

Nevertheless, if water is invaded, a warning message signals the control monitor by temperature and humidity sensors and a warning sound is used to prevent a major failure.

The RoboCrawler S is designed with a double chamber seal structure with Q-ring adopted, completely defending the external water that can be invaded by the axis of the rotating wheel. In addition, unlike the existing products in box-shaped structure when waterproofing mechanisms were penetrated on the axis and the expensive motors and PCBs got damaged immediately, RoboCrawler S has an oil fence inside the Wheel Frame unit, which fundamentally prevents the robot from being damaged by external water.

Nevertheless, if water is invaded, a warning message signals the control monitor by temperature and humidity sensors and a warning sound is used to prevent a major failure.

Twin Motors

The RoboCrawler S is designed with a double chamber seal structure with Q-ring adopted, completely defending the external water that can be invaded by the axis

of the rotating wheel. In addition, unlike the existing products in box-shaped structure when waterproofing mechanisms were

penetrated on the axis and the expensive motors and PCBs got damaged immediately,

RoboCrawler S has an oil fence inside the Wheel Frame unit, which fundamentally prevents the robot from being

damaged by external water.

Nevertheless, if water is invaded, a warning message signals the control monitor by temperature and

humidity sensors and a warning sound is used to prevent a major failure.

It is also the first twin motor tractor to enter a 5-inch small pipeline,

providing the operator with the best maneuverability that is freely

driven in all directions.

The RoboCrawler S is designed with a double chamber seal structure with Q-ring adopted, completely defending the external water that can be invaded by the axis of the rotating wheel. In addition, unlike the existing products in box-shaped structure when waterproofing mechanisms were penetrated on the axis and the expensive motors and PCBs got damaged immediately,

RoboCrawler S has an oil fence inside the Wheel Frame unit, which fundamentally prevents the robot from being damaged by external water.

Nevertheless, if water is invaded, a warning message signals the control monitor by temperature and humidity sensors and a warning sound is used to prevent a major failure.

It is also the first twin motor tractor to enter a 5-inch small pipeline, providing the operator with the best maneuverability that is freely driven in all directions.

Twin Motors

WAW (World and Work Wheel) Life Unit, which can remotely adjust the height of the camera,

is an innovative invention of structural design that cannot be found in any competitive product.

This unit has a structural principle which the camera orbits around the large circular

gear that does not revolve, like how satellite orbits around the earth.

This method allows a small motor to generate a large rotational force, so that the camera can stably

move in vertical direction.

Even if the camera gets moved by external force, the gear will not be damaged nor it will not be broken.

The units that assemble these parts of the tractor can also be replaced and repaired by users simply at the spot.

For example, if the driving motor doesn’t work, then the users can easily replace the motor cylinder by loosening

the two volts by not having to dissemble the robot itself.

The camera head lift unit and the PCB Pack which is the inner part of robot body can also be conveniently replaced by user.

WAW (World and Work Wheel) Life Unit, which can remotely adjust the height of the camera, is an innovative invention of structural design that cannot be found in any competitive product.

This unit has a structural principle which the camera orbits around the large circular gear that does not revolve, like how satellite orbits around the earth.

This method allows a small motor to generate a large rotational force, so that the camera can stably move in vertical direction.

Even if the camera gets moved by external force, the gear will not be damaged nor it will not be broken.

The units that assemble these parts of the tractor can also be replaced and repaired by users simply at the spot.

For example, if the driving motor doesn’t work, then the users can easily replace the motor cylinder by loosening the two volts by not having to dissemble the robot itself.

The camera head lift unit and the PCB Pack which is the inner part of robot body can also be conveniently replaced by user.

Have any questions?

Email or call us anytime.